-

13316809242/15816897019

13316809242/15816897019

-

59911926@qq.com/sales@goldenfuturehk.com

59911926@qq.com/sales@goldenfuturehk.com

13316809242/15816897019

13316809242/15816897019

59911926@qq.com/sales@goldenfuturehk.com

59911926@qq.com/sales@goldenfuturehk.com

Time:2018-09-18 Views:0

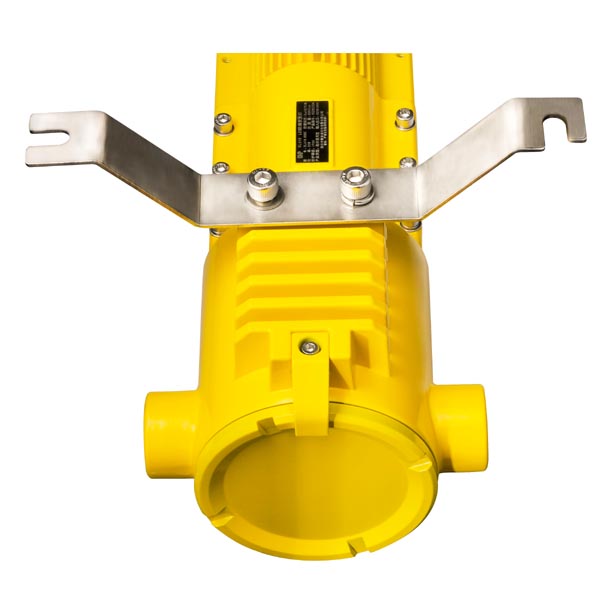

How to determine whether the LED explosion-proof lamp is explosion-proof

LED Explosion-proof Lights Explosion-proof joint structure regulations: When designing molds, the following result elements should be considered.

First item: The maximum clearance of the explosion-proof joint surface of the static part of the electrical equipment, the joystick and the shaft and the explosion-proof joint with the bearing shaft and the corresponding casing volume must comply with the requirements of Table 1. The minimum effective length of the quick-action door type flameproof joint surface is not less than 25mm

The average roughness of the second flameproof joint shall not exceed 6.3 μm.

The third explosion-proof surface has no rust (after rubbing with cotton yarn, there is still rust and rust, but only cloud shadow, not rust).

The fourth item is bolted to the flameproof surface:

1 bolts, spring washers must be complete and fastened (tightening to flatten the gasket to pass).

2 The size of the spring washer must be compatible with the bolt. (Occasionally, when the individual spring washer breaks or loses its elasticity, check the explosion-proof gap. If it is not over-limit, replace the qualified spring washer is not explosive.)

3 bolts or screw holes cannot be slipped (except for those with the same diameter and long bolts and nuts).

4 bolt and impervious screw hole, the axial length of the remaining thread on the bolt and screw hole after tightening should be greater than 1.5 times the thickness of the spring washer; the thickness around the screw hole and the bottom is greater than 3mm.

5 The bolt and nut specifications of the same part should be the same. The depth of the steel fastening bolt screwed into the nut should not be less than the bolt diameter.

6 The length of the counterbore steel fastening bolt extending into the screw hole should be greater than the diameter of the bolt. The cast iron, copper and aluminum parts are not less than 1.5 times the diameter of the bolt; if the screw hole depth is not enough, the hole must be filled.

7 Motor junction box cover must not be reversed.

LED explosion-proof lamps are the special use environment requirements for explosion-proof products, and the principle of safety first. Therefore, products that do not meet the requirements are judged to be non-explosive and should not be used.

1. The scratch on the explosion-proof surface is not perfect. The depth and width are not more than 0.5mm, or the effective width of the non-invasive explosion-proof surface is less than 2/3 of the values specified in Table 1 and Table 2. It is explosion-proof.

2. The width of the cover-type or insert-type explosion-proof surface shall not be less than 25mm, and the clearance shall not be greater than 0.5mm, otherwise it will be detonated. The quick-opening door or cover cannot be opened due to deformation, and the clearance of the explosion-proof surface is greater than or the effective width of the joint surface is less than the value specified in Table 1. Otherwise, it is not perfect.

3. The surface roughness of the explosion-proof surface should be no more than 6.3um, and the roughness of the joystick should be no more than 3.2um, otherwise it will be detonated.

4. There is rust on the explosion-proof surface. After wiping with cotton yarn, there is a “cloud shadow” that is not perfect, and those who still have rust marks are detonated. (Cloud shadow: blue-brown iron oxide cloud-like traces, no touch by hand).

5. There are localized blisters with a diameter greater than 0.5mm and a depth greater than 1mm in the explosion-proof surface. More than 5 in the range of 1cm2 are detonation.

6, there should be no paint and hard debris on the explosion-proof surface, otherwise it will be explosive.

7. The explosion-proof surface should be phosphated or coated with a suitable amount of neutral petroleum jelly and other qualified anti-rust oil (after spraying, Vaseline oil can also be applied), and the phosphorus surface is not coated with anti-rust oil for explosion. It is advisable to apply a layer of film on the explosion-proof surface, and the oil is too much.

LED explosion-proof lamps in the production process, should meet the following parameters, otherwise it is judged as defective reprocessing or waste destruction, can not be used or compromised. LED explosion-proof lamps, LED explosion-proof platform lamps, LED explosion-proof floodlights on the explosion-proof surface, the defects within the specified length and the shortest effective length of the edge of the screw hole to the edge of the explosion-proof surface shall not exceed the following provisions:

1. For the sand holes with a diameter of not more than 1mm and a depth of not more than 2mm, no more than 2 holes per square centimeter on the 40, 25, 15mm flameproof surface.

2. The mechanical damage caused by accident, the width and depth of which are not more than 0.5mm, and the effective length of the remaining non-invasive flameproof surface is not less than 2/3 of the specified length.

3. No paint is allowed on the explosion-proof surface. (When the paint is found, the gap is not exceeded. The length of the joint without the paint is not less than 2/3 of the specified length.)