-

13316809242/15816897019

13316809242/15816897019

-

59911926@qq.com/sales@goldenfuturehk.com

59911926@qq.com/sales@goldenfuturehk.com

13316809242/15816897019

13316809242/15816897019

59911926@qq.com/sales@goldenfuturehk.com

59911926@qq.com/sales@goldenfuturehk.com

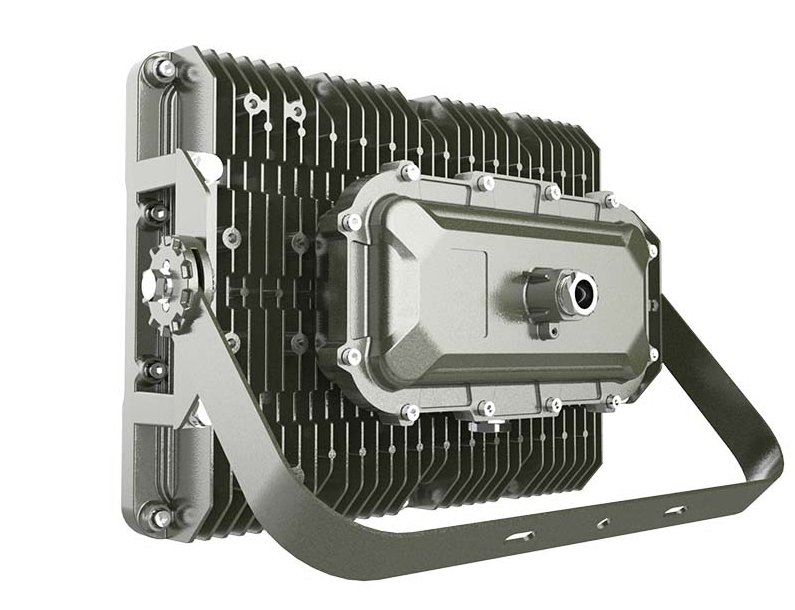

Model No:DL260L

Input voltage:AC220-240v

Lighting angle: 90°

Led source: Cree led, 120lm/w

PF>0.95 CRI:Ra>70

Ex mark: Ex d IIC T6

Waterproof grade:IP66;

Corrosion proof:WF2

Weight: 12.5KG

Size: 472×315×165mm

DL260L LED Explosion Proof Lighting for IIA, IIB, IIC Explosive Gas Environment

This product has good explosion-proof function, suitable for IIA, IIB, IIC explosive gas environment and various inflammable and explosive places, mainly used in railway, electric power, metallurgy, petroleum, petrochemical, chemical, steel, aviation, ship and each Efficient lighting in factories, stations, large facilities, venues and other places.

Product Features :

1 . Configuration: It adopts imported LED light source, with an average service life of up to 100,000 hours. The power supply adopts wide voltage processing, which can realize constant current output, and has short-circuit and over-voltage protection functions, which greatly prolongs the service life of the lamps.

2 . Heat dissipation:explosion-proof electrical box and lamp holder double cavity design, large space size to ensure the assembly of various large-scale electrical appliances. Excellent heat dissipation performance, so that the LED chip and power supply temperature rise is reasonably controlled within a reasonable range, greatly ensuring the service life of the lamp .

3 . Light distribution: light projection is even and soft, especially suitable for all kinds of need to cast light, floodlights as a fixed lighting.

4 . Protection: The protection level of the lamp body is IP66, and the anti-corrosion level can reach WF2. The surface of the lamp body will never corrode and never rust.

5 . Installation method: Various installation methods such as ceiling, suction wall and U-shaped anti-vibration bracket (angle adjustable) can be used as needed.

| ITEM | Description | UNIT |

Rated Voltage | AC220 | V |

| Power | 200-280 | W |

| Protection Level | IP66 | |

| Lighting Angle | 90 | ° |

| LED Qty | 250 | pcs |

| Explosion proof grade | Ex d e mb IIC T6 | |

| Light efficiency | 120 | Lm/W |

| Frequency | 50/60 | Hz |

| Power Factor | >0.95 | PF |

| Operating Temperature | -30~50 | ℃ |

| Storage Temperature | -30~50 | ℃ |

| Correlate Color Temperature | 3000-6500 | K |

| Color Rendering Index | ≥70 | RA |

| LED'S Operating Life | 100000 | Hours |

| Start-up time | ≤0.2 | S |

| Executive standard | GB3836.1 GB3836.2 | |

| Size | 472×315×165 | mm |

| Weight | 12.5 | kg |

13316809242 / 15816897019

13316809242 / 15816897019

59911926@qq.com / sales@goldenfuturehk.com

59911926@qq.com / sales@goldenfuturehk.com

Room 1703, Pearl River International Center, No. 9009 Longxiang Avenue, Central City, Longgang District, Shenzhen

Room 1703, Pearl River International Center, No. 9009 Longxiang Avenue, Central City, Longgang District, Shenzhen